Intelligent Palletizing Robots for Efficient Automation

30 Years of Expertise | Compact Design | Save 60% Labor Cost

Advantage of Palletizing Robot

Improve efficiency

Save labor costs

Accurate and neat stacking

Diverse products with strong compatibility

Improve production safety

Small footprint and flexible layout

Can be seamlessly connected with the automation system

Stable operation and low maintenance cost

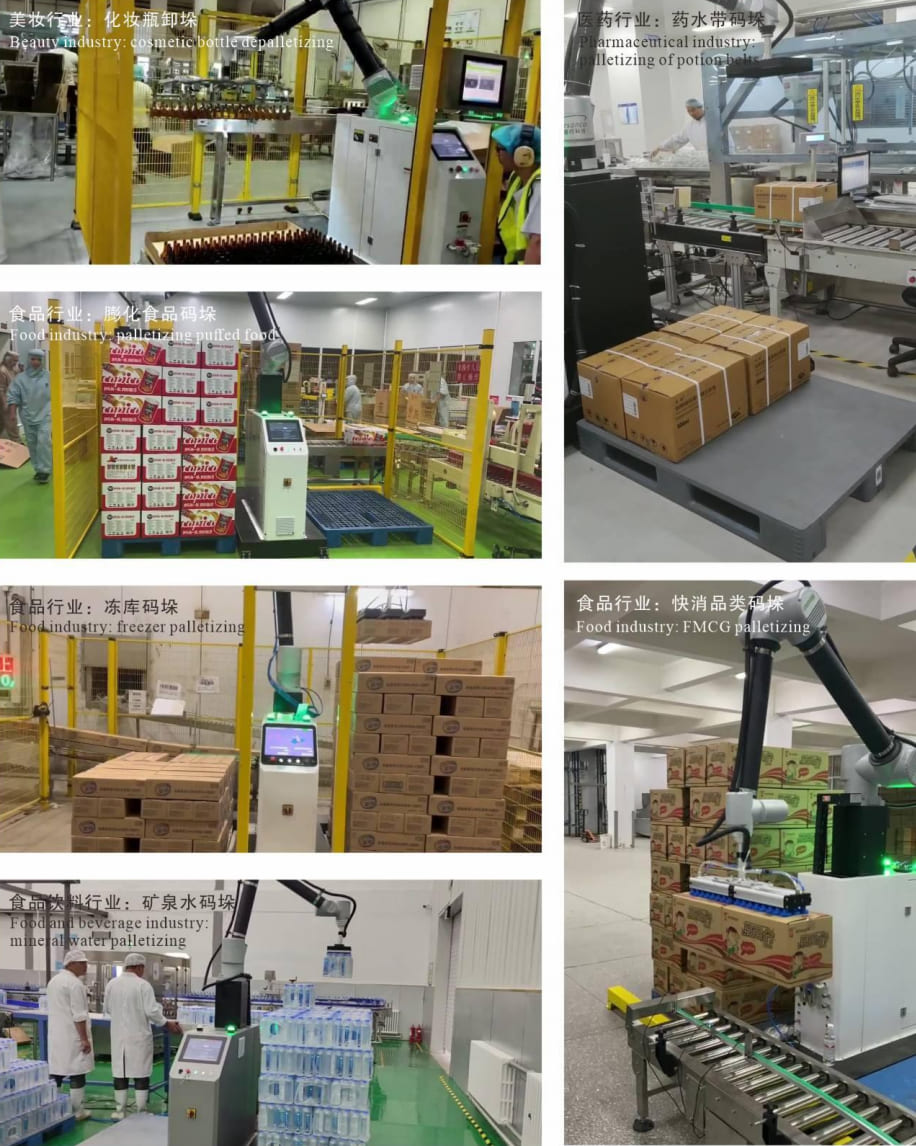

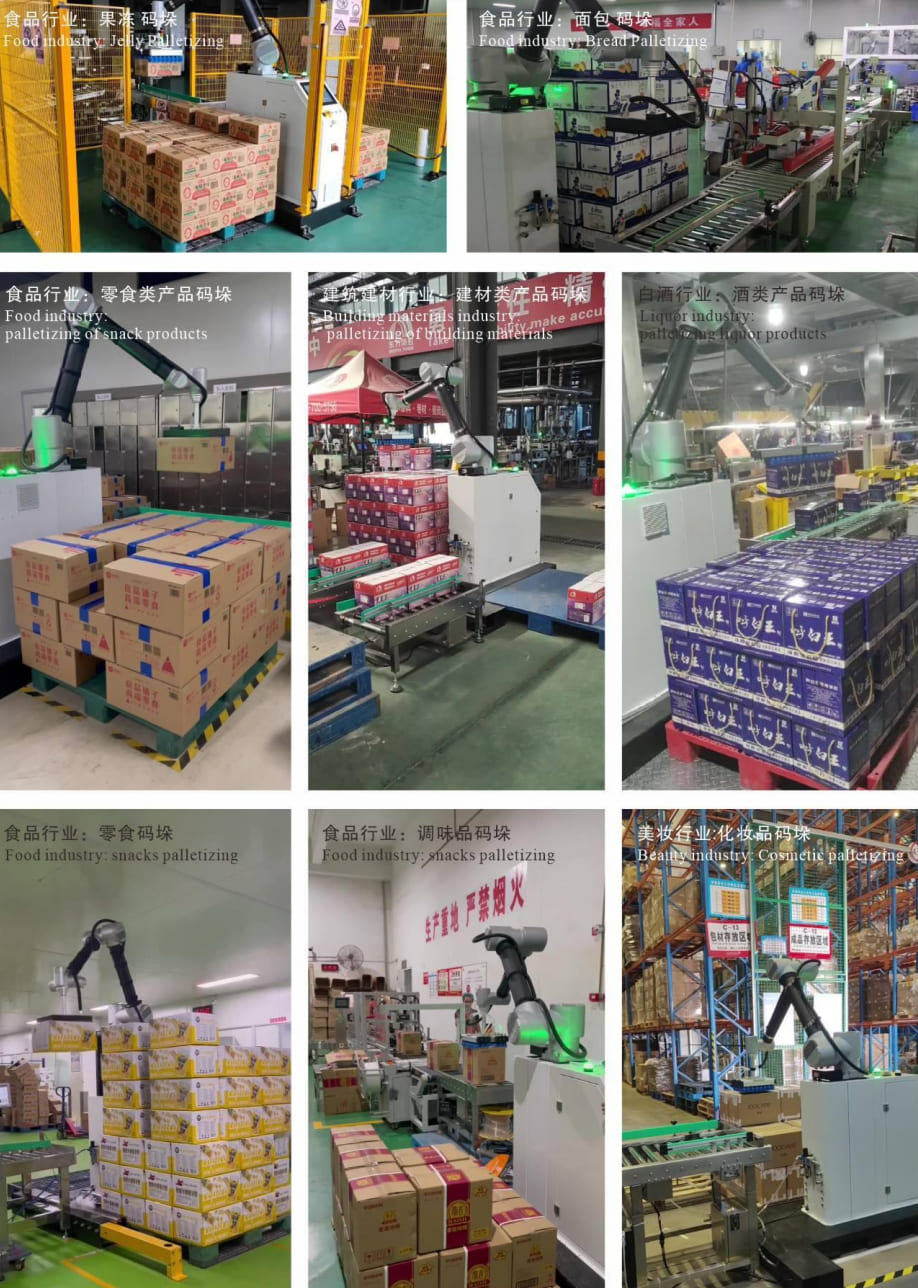

Real use scenarios of palletizing robots

Palletizing robots are suitable for food, chemical, construction, daily chemical products, medicine, logistics warehousing, animal husbandry, and agricultural products industries.

1) Palletizing speed: 8-10 times/minute (depending on the product);

2) Pallet size: L1200mm-W1200mm-H150mm ;

3) Pallet placement: manual, one left and one right (Or option as AGV Palletizing Robot);

4) Robot load-bearing capacity: 20/30/50/60/ kg including grippers;

5) Palletizing height: maximum palletizing height 2500mm, lifting column 600mm;

6) Servo control; 7)Clamps: suction cups, grippers (according to product design) 8)Supports a wide range of packaging types—bags, cartons, drums, etc.—with automatic gripper adjustment for multi-product compatibility.

What is Palletizing Robot

A palletizing robot is an intelligent industrial machine designed for the automated handling and stacking of products onto pallets. Commonly used at the end of production lines, the palletizing robot efficiently and orderly stacks packaged products—such as cartons, bags, and barrels—onto pallets based on predefined patterns, improving automation, storage efficiency, and logistics operations.

Features of Soontrue's Palletizing Robot

Palletizing robot can automatically identify and pick up products of various shapes and sizes through vision systems or sensors, enhancing overall automation.

Palletizing robot stacks products neatly according to predefined patterns (e.g., straight or interlaced), ensuring pallet stability and efficient outbound logistics.

Palletizing robot supports a wide range of packaging types—bags, cartons, drums, etc.—with automatic gripper adjustment for multi-product compatibility.

Palletizing robot allows programmable stacking logic and quick product changeover, adapting easily to different production requirements.

Palletizing robot integrates seamlessly with conveyors, packaging machines, and AGV carts to enable full-process automation.

Palletizing robot supports remote monitoring and fault alerts for easier management and continuous operation.

What others are saying about Soontrue's Palletizing Robot

Soontrue’s Palletizing Robot are widely recognized by customers

Somchai Rattanakorn - Supermarket Owner, Thailand

“As the owner of a busy supermarket chain in Bangkok, efficiency is everything. Since integrating the palletizing robot into our warehouse, we’ve cut down restocking time by nearly 40%. The robot handles heavy loads with precision, and its compact design fits perfectly in our limited space. Our staff can now focus on customer service instead of manual stacking. It’s been a game-changer for our operations!”

James Carter -Consumer Goods Factory Owner, USA

“Running a consumer goods factory in Ohio, we needed a solution to keep up with high demand. The palletizing robot has exceeded expectations. It’s fast, reliable, and handles our diverse product range without a hitch. We’ve seen a 30% increase in throughput, and workplace injuries from manual lifting are down to zero. Worth every penny for boosting productivity!”

Anna Müller - Food Processing Plant Manager, Germany

“In our food processing plant near Munich, precision and hygiene are non-negotiable. The palletizing robot meets both standards effortlessly. Its stainless steel components are easy to clean, and the automated stacking ensures perfect uniformity, which is crucial for our export clients. The robot’s integration with our existing systems was seamless, and it’s been running smoothly for months. Fantastic investment!”

Lucía Fernández - Frozen Food Factory Manager, Uruguay

“In our frozen food facility in Montevideo, maintaining a cold chain is critical. The palletizing robot has been a reliable addition, operating flawlessly in our low-temperature environment. It stacks pallets with consistent accuracy, reducing product damage and speeding up our shipping process. The ease of programming also means we can adapt quickly to different pallet sizes. Highly recommend it!”

Why Choose Soontrue

30+ years

Founded in 1993.Soontrue is the first to independently develop and manufacture packaging machines.

138 enginners

There are 138 engineers in Soontrue’s packing machine production plant, 89 of whom have more than 20 years of experience.

Capacity guarantee

Capacity guarantee

Direct supply from our 30,000㎡ Soontrue factory, standard models delivered within 7 days, 30% faster than the industry

99.98%

After years of research, the qualified product rate of Soontrue flow packing machine is 99.98%.

International Standards

International Standards

Soontrue Packaging Machinery has 25 years of global export experience. All products have passed CE certification and provide customized testing services to meet your special needs.

5S Management

5S Management

5S standardized production management and strict control of the entire process ensure the high precision and reliability of each device

Test 72 hours

Soontrue’s pillow machines will undergo 72 hours of continuous operation after being assembled by the assembly robot, which is supervised by the quality control department.

8000+ customers

Soontrue supplies packing machines to over 8,000 factories and fully automated packaging systems to over 960 factories.

Assess Client Packaging Needs

Assess client packaging needs, including product type, bag size, speed requirements, and specific requests.

Design & Quote Packaging Solution

Engineers design packaging solution, provide quote, and process order.

Manufacture, Test, and Ship Machine

Manufacture machine, run continuously for 8 hours, conduct final quality inspection before shipping.

Production Process

Our machine’s quality assurance stems from rigorous production process standards.

1.Design by engineer

Understanding the customer’s packaging requirements, product dimensions and site information ensures that needs are accurate and clear. A team of engineers uses this data to design customized packaging solutions that meet the customer’s productivity and site constraints.

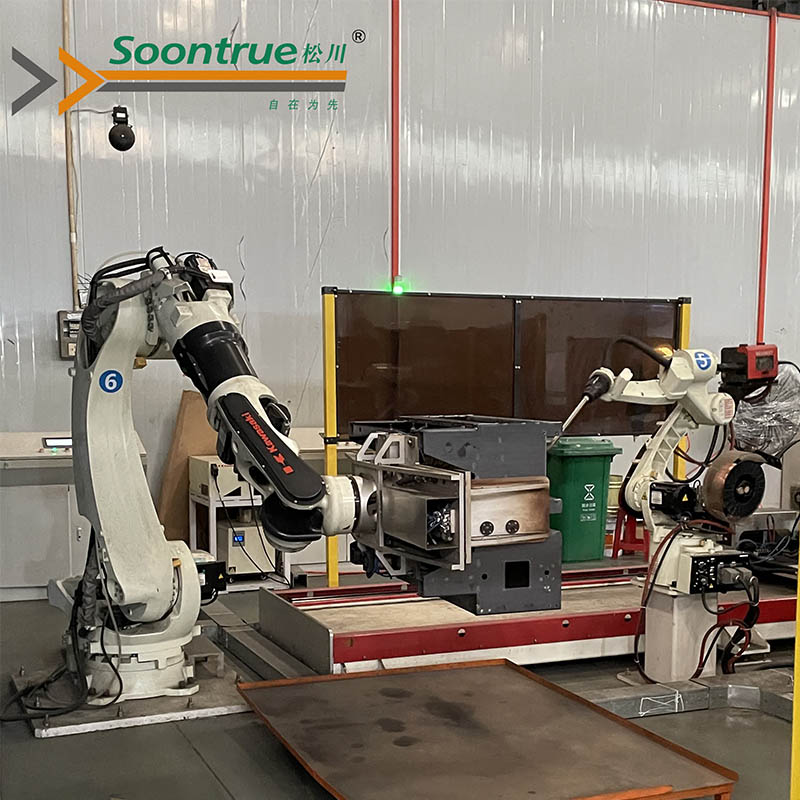

2.Sheet metal robots

Since 2020, Soontrue has introduced sheet metal robots; increased efficiency and quality assurance.

3.Assembly department

The assembly department is responsible for the assembly of each component separately and has to run continuously on the test machine for 72 hours to ensure that the components operate normally.

4.Accessory nameplates

Components can be labeled only after 72 hours of continuous operation and passing the inspection of the quality control department, which is convenient for management and after-sale convenience of replacement parts.

5.Assembly robot warehouse

The parts are put into the warehouse where the robot is assembled after being labeled with a nameplate.

6.Assembling robots

Soontrue is the first packaging machine manufacturer in China to introduce assembly robots, which can produce 45 packaging machines per day and improve production efficiency.

7.Test machine by sample

After the machine is assembled, there is a specialized team of commissioning engineers to commission the machine according to the customer’s product and will run the test continuously for 72 hours.

8.Quality control department

After the test is completed, the quality inspection department will inspect the packaging machine and fill in the form and take photos to leave a record, after passing the inspection, the nameplate will be affixed to the packaging machine to facilitate the after-sales department to replace the parts.

9.Packing and shipping

After the packaging machine finishes production and inspection, the shipping department is responsible for packing and shipping. The packing department will wrap the machine with pearl cotton, plastic film and export wooden crates to avoid damage to the machine during transportation.

About Soontrue

Soontrue: Pioneering Packaging Innovation for 30 Years

Welcome to Soontrue, a visionary leader in packaging equipment automation and smart factory innovation, headquartered in Foshan, Guangdong, since its founding in 1993. As Foshan’s first manufacturer of flow pack machines and a trailblazer in China’s independent development of packaging and food packing machinery, Soontrue stands as a benchmark brand in China’s packaging automation industry.

Soontrue seamlessly integrates the research, development, and manufacturing of automated products with comprehensive enterprise automation solutions, full-factory intelligent coverage, and extended services. With a diversified, streamlined operational model, we operate across four major bases in Shanghai, Foshan, Chengdu, and Jiaxing, delivering “all-in-one, all-heart” excellence.

For over three decades, Soontrue has been a pioneer and innovator in China’s automated food production, packaging, and machinery sectors. Guided by our core belief of “Dedicated Excellence, Inclusive Vision” and our market philosophy of “Putting Customer Needs First,” we champion craftsmanship, drawing on deep expertise to create human-centered designs that deliver exceptional value. Today, Soontrue is a flagship brand in China’s plastic bag packaging equipment and food packing machine industry.

We boast a powerful industry advantage with “diverse products and comprehensive services,” serving a wide range of sectors. Our solutions lead the market in snack foods & seasonings, baked goods, chemicals, frozen foods, pharmaceuticals, agriculture & seafood, and hardware & daily essentials, setting the standard for excellence.

Our independently designed flow pack machine automated assembly systems are redefining the future of automation in China’s packaging machinery sector, driving new directions for industry growth. Looking ahead, Soontrue boldly pioneers the future of automated machinery, expanding into intelligent robotic arms and automated kitchens, redefining smart production concepts to achieve our vision of becoming “a trusted, all-in-one mechanical equipment service provider.”

Currently, Soontrue serves over 20,000 enterprises with integrated packaging systems and solutions, solidifying our indispensable role in the packaging equipment industry. With the motto “Innovation Creates a Seamless Life,” we partner with clients and collaborators to build an open, inclusive ecosystem, co-create value, identify growth opportunities, and steadily advance toward Industry 4.0. Soontrue—your trusted partner for comprehensive mechanical equipment solutions.

Frequently Asked Questions

Q1: What types of Palletizing Robot do you offer?

- Robotic Arm Palletizers – Ideal for flexible palletizing of cartons, bags, buckets, etc., with multi-axis movement and space-saving design.

- Collaborative Palletizers (Cobot) – Safe to work alongside humans, perfect for compact spaces and lighter payloads.

- Customized Palletizing Systems – Tailored solutions for special product sizes, mixed product lines, or integration with AGVs and conveyors.

Q2: What is warranty and after-sale service

All of Soontrue’s packaging machines have an extra-long 24-month warranty period and provide lifetime free technical consulting support. We promise: each customer will be equipped with a dedicated technical engineer to respond to your needs 24 hours a day – telephone guidance, remote video conference diagnosis in one step. For large equipment, you can also make an appointment for engineers to provide on-site installation services, with one-on-one follow-up throughout the process, to ensure that you have a worry-free connection from installation to later maintenance! “

Q3: What technical support is available if I purchase your Palletizing Robot?

For all our bakery automatic packaging systems, including those for biscuits, cookies, and bread, we offer 24/7 online technical support. We also provide instructional videos covering installation, daily commissioning, and maintenance. For customized systems, our professional after-sales technicians can offer on-site installation and commissioning services upon request (note: the buyer is responsible for associated costs).

Q4: How can we establish trust for our first transaction?

We believe trust is built through professional service and superior product quality. Our team will thoroughly assess your requirements and clearly explain our products and solutions to ensure full transparency. We can arrange a virtual tour of our modern factory via video call to showcase our production processes and product quality. Before delivery, we support factory acceptance testing (FAT) in collaboration with your partners or through test videos/video calls, ensuring the automatic packaging system meets your expectations prior to shipment.

Q5: How can I identify the most suitable automatic packaging system for my needs?

We engage in detailed discussions to understand your product specifications, packaging requirements, and feeding methods. With nearly 30 years of experience as an automatic packaging system manufacturer, we can share relevant case studies and videos for reference. If needed, we may request product and packaging film samples for testing to deliver the most cost-effective and optimized solution tailored to your requirements.

Q2: I’m concerned about operating your machines. Are they user-friendly?

Contact Form

Request a Quote for Your Packaging Solution